PolyArmor® Conveyors

Mayfran’s PolyArmor® conveyors are used in recycling, particularly for long conveyor lengths, high vertical lift and high belt speed. These conveyors also are appropriate for combined material applications, laser applications with high temperatures up to 700° F, as well as applications where laminated scrap, glass, small fasteners and small parts are being handled.

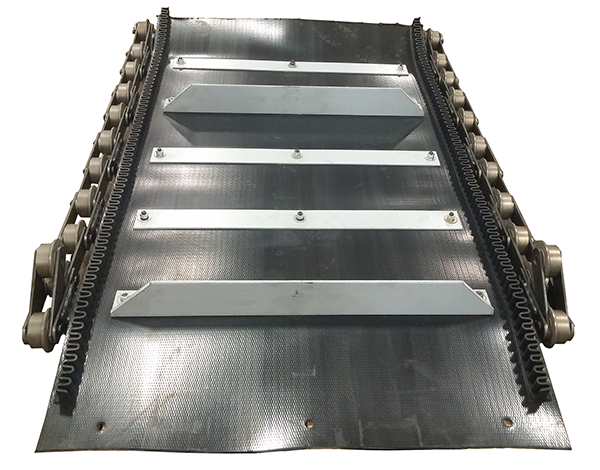

PolyArmor® conveyors are impact resistant, rip resistant, low stretch, high cover adhesion and are cut, gouge and tear resistant. The PolyArmor® conveyors are available in either open- or closed-frame construction. Mayfran offers its PolyArmor® conveyors in pitches of 2.5″, 6″ or 9″, depending on load and temperature specifications.

Mayfran’s PolyArmor® conveyors also come with several application-specific options, including:

- Vulcanized urethane belt covers (1/16″, 1/8″ or 3/8″ thick)

- Vulcanized corrugated side walls (from 1″ to 4″ high)

- Angle or vulcanized “beefy” cleats

- Steel belt supports with studs welded to conveyor belt chain

- Impact shoes

- Hardened short pins

- Variable speed drives

The PolyArmor® conveyors are energy efficient and optimized for scrap loads. They are easy to maintain and install and offer safety measures to protect workers. Our application engineers can work with you to develop your specifications for your particular application.